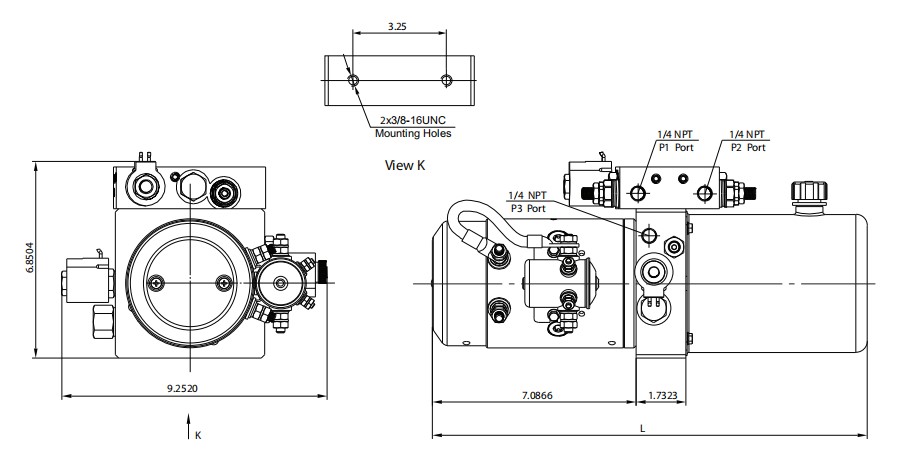

General Description

Consisting of a stress balanced gear pump, DC motor, multi-functional manifold, valves, tank, ect., this energy unit is created to operate material dealing with products. The lowering motion is achived from the solenoid valve with the decreasing velocity managed by an adjustable needle valve. The left and ideal functions are equipped that has a dual pilot operated check out valve and cross-over relief valves.

Remark: Please check with our revenue engineer to the diverse pump displacement, motor electrical power or tank capability.

Special Notes

one. This energy unit is of S3 duty cycle, i.e.,non-continuous operation,thirty seconds on and 270 seconds off.

2. Clean all the hydraulic parts concerned in advance of installation of the electrical power unit.

three. Viscosity from the hydraulic oil shoud be 15~46 cst, which must also be  clean and absolutely free of impurities.N46 hydraulic oil is recommended.

clean and absolutely free of impurities.N46 hydraulic oil is recommended.

four. This energy unit should be mounted horizontal.

5. Check the oil level in the tank soon after the 1st start out with the power unit.

six. Oil changing is needed following the initial one hundred operation hours, afterwards when each 3000 hours.

cardan coupling

As one of leading cardan coupling manufacturers, suppliers and exporters of mechanical products, We offer cardan coupling and many other products.

Please contact us for details.

Mail:[email protected]

Manufacturer supplier exporter of cardan coupling.

Recent Posts

- China Best Sales Large Size Standard Telescopic Flange Cardan Shaft Coupling

- China Custom Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

- China Best Sales High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto Coupling Double Front Rear Best Universal Joint

- China Custom Cross Joint/Drum Tooth Coupling/Cardan Shaft/Drive Shaft/Universal Joint

- China high quality Various Good Quality SWC-Bh Cardan Shaft Standard Flex Welding Type Universal Coupling

- China OEM High Precision Universal Joint Coupling SWC Standard Welding Type Cardan Shaft Coupling

- China Standard Cardan Shaft, Universal Joint, Shaft Coupling, Universal Coupling, S-040

- China Standard Rolling Mill Universal Joint Coupling / Cardan Shaft

- China supplier Cross Joint/Drum Tooth Coupling/Cardan Shaft/Drive Shaft/Universal Joint

- China Professional Made in China New Product Steering Universal Joint Pin and Block R Gimbal Cardan Drive Shaft Universal Joints Coupling

- China Professional High Performance Cardan Type SWC-Wf Integral Plug Cross Shaft Cardan Coupling

- China Good quality Swp-C Short Cardan Shaft Coupling Flexible Coupling Cross Quick Coupling Universal Joint Coupling Flexible Coupling

- China Professional Precision Steering Shaft Double Hardy Spicer Cardan Moog Drive Car Jeep Truck Automobile Heavy Duty Small Axle Universal U Coupling Joints

- China wholesaler Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China OEM Custom Wholesale Cardan Shafts High Precision Wsp Small Cross Shaft Universal Coupling

- China best Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

- China factory High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto Coupling Double Front Rear Best Universal Joint

- China high quality Cross Joint, Drum Tooth Coupling, Cardan Shaft, Coupling

- China OEM Swp-B Cardan Shaft Coupling for Industry Machinery in China

- China best SWC-Wd Universal Joint Coupling Shaft Cardan Shaft Coupling for Transportation Machinery

- China supplier High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto Coupling Double Front Rear Best Universal Joint

- China Best Sales High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto Coupling Double Front Rear Best Universal Joint

- China Professional Hot Sales Wide Range Cardan Coupling SWC Type Cross Shaft Universal Coupling

- China Professional Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China factory Swp-B Cardan Shaft Coupling for Industry Machinery in China

- China Custom SWC-Wd Universal Joint Coupling Shaft Cardan Shaft Coupling for Transportation Machinery

- China Best Sales High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto Coupling Double Front Rear Best Universal Joint

- China OEM Hot Sales Wide Range Cardan Coupling SWC Type Cross Shaft Universal Coupling

- China Good quality Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China wholesaler Flexible Stainless Steel Spider Couplings Balancing Machine for Cardan Shafts

- China OEM Perrot Cardan Couplings (lever couplings)

- China factory Precision Steering Shaft Double Cardan Moog Drive Car Jeep Truck Automobile Heavy Duty Small Axle Universal Elastic Coupling

- China supplier Fql 291 China Cardan Shaft Cross Bearings Joint Universal Coupling Manufacture SWC-I120b-295

- China best Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China Standard No Telescopic Shorten Universal Cardan Shaft Coupling (SWC WD)

- China Hot selling SWC-Wf No Flexible Short Mechanical Universal Cardan Shaft, Universal Joint, Universal Coupling

- China wholesaler Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

- China Hot selling Short Telescopic Welding Cardan Shaft Coupling

- China Good quality Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China factory No Telescopic Shorten Universal Cardan Shaft Coupling (SWC WD)

- China wholesaler SWC-Wf No Flexible Short Mechanical Universal Cardan Shaft, Universal Joint, Universal Coupling

- China Best Sales Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

- China manufacturer Short Telescopic Welding Cardan Shaft Coupling

- China Professional Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China high quality CHINAMFG Swp-E Type Telescopic Flange Long Cardan Shaft Coupling

- China factory Cardan Shaft, Universal Joint, Shaft Coupling, Universal Coupling, S-040

- China high quality Flexible Joint Coupling SWC-Bh Cardan Shaft Standard Flex Welding Type Universal Coupling

- China OEM No Telescopic Long Cardan Shaft Coupling (SWP-D)

- China high quality Cross Joint, Drum Tooth Coupling, Cardan Shaft, Coupling

- China manufacturer Swp-C Short Cardan Shaft Coupling Flexible Coupling Cross Quick Coupling Universal Joint Coupling Flexible Coupling

- China high quality High Quality Hardy Spicer Cardan Constant-Velocity Propshaft Steering Shaft Removing Pto Coupling Double Front Rear Best Universal Joint

- China manufacturer Precision Steering Shaft Double Cardan Moog Drive Car Jeep Truck Automobile Heavy Duty Small Axle Universal Elastic Coupling

- China supplier High Precision Universal Joint Coupling SWC Standard Welding Type Cardan Shaft Coupling

- China high quality Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China Professional SWC Series Cardan Shaft Coupling for Machine

- China factory Custom Made Short Telescopic Cardan Shaft Universal Coupling

- China Good quality Custom Made Short Telescopic Cardan Shaft Universal Coupling

- China wholesaler Swp-B Welded Short Shaft Universal Coupling Cardan Shaft Cross Quick Coupling Universal Joint Coupling

- China high quality SWC-Bh Standard Welding Type Cardan Shaft Couplings

- China Professional Precision Steering Shaft Double Cardan Moog Drive Car Jeep Truck Automobile Heavy Duty Small Axle Universal Elastic Coupling

- China Standard Hot Sales Wide Range Cardan Coupling SWC Type Cross Shaft Universal Coupling

- China OEM CHINAMFG Swp-E Type Telescopic Flange Long Cardan Shaft Coupling

- China Standard High Quality SWC Industrial Flexible Steel Propeller Universal Joint Cardan Shaft Coupling

- China Professional Precision Steering Shaft Double Cardan Moog Drive Car Jeep Truck Automobile Heavy Duty Small Axle Universal Elastic Coupling

- China Hot selling Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

- China supplier Customized Size High Quality Cardan Shaft Universal Coupling