Product Description

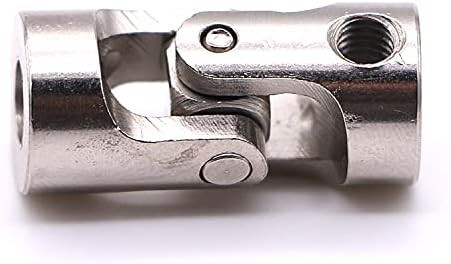

high quality Hardy Spicer Cardan Constant-velocity propshaft steering shaft removing pto coupling double front rear best universal joint

Application of Universal Joint

Universal joints (also called U-joints) are mechanical joints that allow 2 shafts to rotate at different angles. They are commonly used in vehicles, machinery, and other mechanical systems where the shafts need to be able to move independently of each other.

Universal joints are made up of 2 yokes and a cross. The yokes are attached to the shafts, and the cross is located at the center of the yokes. The cross allows the shafts to rotate at different angles while still maintaining a connection between the 2 shafts.

Universal joints are used in a variety of applications, including:

- Vehicles: Universal joints are used in vehicles to connect the driveshaft to the wheels. The driveshaft needs to be able to move up and down as the suspension moves, and the universal joint allows the driveshaft to do this while still transmitting power to the wheels.

- Machinery: Universal joints are used in machinery to connect rotating shafts. For example, they are used in conveyor belts to connect the driveshaft to the belt.

- Other mechanical systems: Universal joints are used in a variety of other mechanical systems, such as wind turbines, cranes, and robots.

Universal joints are a versatile and reliable type of joint that is used in a wide variety of applications. They are a cost-effective option for many applications, and they offer a number of advantages over other types of joints, such as their ability to transmit power between shafts that are not aligned.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Phasing in Cardan Couplings and Its Impact on Performance

The concept of phasing in cardan couplings refers to the alignment of the universal joints’ yokes or flanges on the input and output shafts. Proper phasing is essential to minimize angular misalignment and maintain smooth rotational motion. When the yokes of the universal joints are not aligned correctly, it can result in uneven torque transmission, increased wear, and vibrations.

Phasing affects the performance of cardan couplings in several ways:

- Uniform Torque Transmission: Proper phasing ensures that torque is evenly distributed between the input and output shafts, reducing the risk of overloading individual universal joints.

- Reduced Vibrations: Correctly phased universal joints minimize angular misalignment, which helps reduce vibrations and noise in the machinery system.

- Extended Lifespan: Improved phasing leads to reduced wear and stress on the universal joint components, extending the overall lifespan of the coupling.

- Efficient Power Transmission: Proper phasing contributes to efficient power transmission by minimizing energy losses due to misalignment.

To achieve proper phasing, manufacturers often provide guidelines or marks on the coupling components to ensure accurate alignment. It’s essential to follow these guidelines during installation and any maintenance or adjustments to maintain optimal performance and reliability of the cardan coupling.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-02-13