Product Description

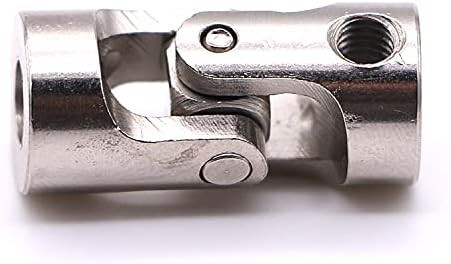

SWC- DH short flex welding type cardan shaft universal coupling

Description:

A universal joint, (universal coupling, U-joint, Cardan joint, Hardy-Spicer joint, or Hooke’s joint) is a joint or coupling in a rigid rod that allows the rod to ‘bend’ in any direction, and is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges located close together, oriented at 90° to each other, connected by a cross shaft. The universal joint is not a constant velocity joint.

No machine element other than a cardan shaft allows power transmission of torque between specially offset driving and driven shafts whose position can be changed during operation.

Spatial angular motion and changes of axial length are ensured by advanced constructional elements.

Thus, cardan shafts have become an indispensable transmission component in automotive engineering and industry.

Features:

1.Gyration diameter:58~620mm

2.Nominal torque:0.15~1000KN*m

3.Max angular misalignment: 25o

4.Reasonable configuration,high safety and long service life

5.High transmission efficiecy:98.6%

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Suitability of Cardan Couplings for High-Speed and Heavy-Duty Applications

Cardan couplings are well-suited for a wide range of applications, including high-speed and heavy-duty ones. Here’s why:

- High Torque Capacity: Cardan couplings can handle substantial torque loads, making them suitable for heavy-duty machinery and equipment.

- Angular Misalignment: They can accommodate significant angular misalignment, which is common in applications with varying shaft angles.

- Smooth Transmission: Cardan couplings provide smooth and continuous power transmission, essential for precision and stability in high-speed applications.

- Robust Construction: They are often built with durable materials and designed to withstand the stresses of heavy loads and high speeds.

- Shock Absorption: The flexibility of cardan couplings allows them to absorb shocks and vibrations, minimizing the impact on machinery components.

- Versatility: Cardan couplings can connect shafts of different sizes and types, allowing for versatility in various applications.

- Reliable Performance: When properly maintained and installed, cardan couplings offer reliable and consistent performance even in demanding conditions.

However, while cardan couplings are suitable for many high-speed and heavy-duty applications, it’s essential to consider factors such as alignment, lubrication, and maintenance to ensure optimal performance and longevity.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2023-12-14