Demanded length of roller chain

Applying the center distance involving the sprocket shafts and the amount of teeth of the two sprockets, the chain length (pitch variety) may be obtained through the following formula:

Lp=(N1 + N2)/2+ 2Cp+{( N2-N1 )/2π}2

Lp : Total length of chain (Pitch amount)

N1 : Quantity of teeth of compact sprocket

N2 : Quantity of teeth of massive sprocket

Cp: Center distance involving two sprocket shafts (Chain pitch)

The Lp (pitch quantity) obtained through the over formula hardly turns into an integer, and usually incorporates a decimal fraction. Round up the decimal to an integer. Use an offset website link if your number is odd, but decide on an even quantity around feasible.

When Lp is determined, re-calculate the  center distance among the driving shaft and driven shaft as described while in the following paragraph. In case the sprocket center distance are unable to be altered, tighten the chain making use of an idler or chain tightener .

center distance among the driving shaft and driven shaft as described while in the following paragraph. In case the sprocket center distance are unable to be altered, tighten the chain making use of an idler or chain tightener .

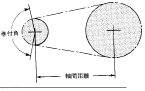

Center distance among driving and driven shafts

Naturally, the center distance involving the driving and driven shafts have to be much more compared to the sum of your radius of both sprockets, but on the whole, a suitable sprocket center distance is regarded as to get 30 to 50 times the chain pitch. However, when the load is pulsating, twenty instances or significantly less is appropriate. The take-up angle involving the smaller sprocket and the chain must be 120°or more. Should the roller chain length Lp is offered, the center distance involving the sprockets might be obtained in the following formula:

Cp=1/4Lp-(N1+N2)/2+√(Lp-(N1+N2)/2)^2-2/π2(N2-N1)^2

Cp : Sprocket center distance (pitch variety)

Lp : General length of chain (pitch variety)

N1 : Number of teeth of little sprocket

N2 : Quantity of teeth of significant sprocket